We are conducting various researches to develop technologies for future gravitational wave detectors

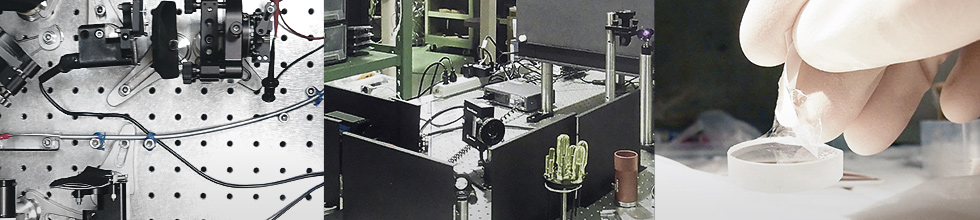

Development of frequency dependent squeezed vacuum source to improve the sensitivity of the gravitational wave detector KAGRA.

KAGRA will be the first gravitational wave detector based on a long-baseline laser interferometer that will be operated at cryogenic temperatures. As a consequence its sensitivity will be limited by quantum noise over most of its frequency band. By injecting squeezed vacuum states with a frequency dependence matched to the KAGRA sensitivity, it is possible to reduce the quantum noise and improve its sensitivity to gravitational waves. At NAOJ we are using the infrastructure that hosted the TAMA300 interferometer to develop a 300-m long filter cavity. This cavity, coupled with a squeezed vacuum source, will produce frequency-dependent squeezed vacuum states. This experiment is being done in collaboration with other groups in Europe.

Development of crystalline coatings for laser interferometers devoted to gravitational wave detectors.

Nowadays, gravitational wave detectors based on long-baseline laser interferometers are limited by thermal noise in their test masses. In particular, the coating material used to provide the test masses with very high reflectivity turns out to be the main source of thermal noise. At NAOJ we are working on the development and testing of a new type of coating based on crystalline materials. Indeed, crystals have much lower thermal noise than the dielectric materials presently used for the high reflectivity coatings. This difference is even larger at the cryogenic temperatures at which KAGRA will operate. But realizing crystalline coatings with large size and excellent optical quality remains a challenge and an intense R&D program is required.

Direct measurement of coating thermal noise at cryogenic temperature

In order to measure the thermal noise performance of new coating technologies, we are developing a facility to directly measure the thermal noise of mirrors at cryogenic temperatures. This facility makes use of a low-vibration cryostat (technology developed for KAGRA) as well as two optical cavities made of silicon. By comparing the length fluctuations of the two cavities, we can extract the thermal noise component of the fluctuations. By feeding back the measurement results to the coating processes, we hope to realize better coatings.

Optical absorption measurements

KAGRA test masses will be cooled down to 20K in order to reduce thermal noise. Sapphire mirrors will be used because of their good thermal conductivity at low temperature. In order to enhance the cooling-down procedure, the mirrors' optical absorption needs to be investigated and minimized. An experiment for characterizing the surface and bulk absorption properties has been set up in NAOJ. The photothermal common path interferometer (PCI) method is used. Making the proper calibrations, we have measured the optical absorption of many samples, up to 2 inches diameter. We are currently upgrading the system to also measure large size mirrors and GaAs/AlAs crystalline coatings for future upgrades of KAGRA.

Scattering characterization systems

Scattering of light from the various optical elements is one of the sources of noise in gravitational wave detectors like KAGRA. As the sensitivity of gravitational wave detectors becomes better and better, the scattering is becoming more and more an issue. Thus, characterization and understanding of scattering processes is key to the development of better detectors. We have built two devices for measuring the hemispherical and the back- or retro-scattering, respectively, of differently sized samples and are performing measurements on the scattering of surfaces of materials that are (or going to be) used in large scale interferometers like KAGRA.